3 SEPARATION SYSTEMS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to 3 SEPARATION SYSTEMS

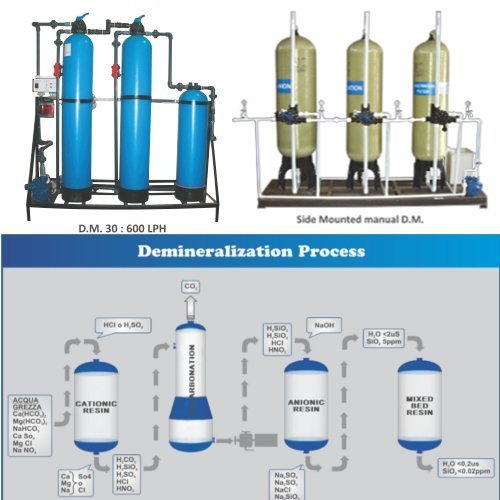

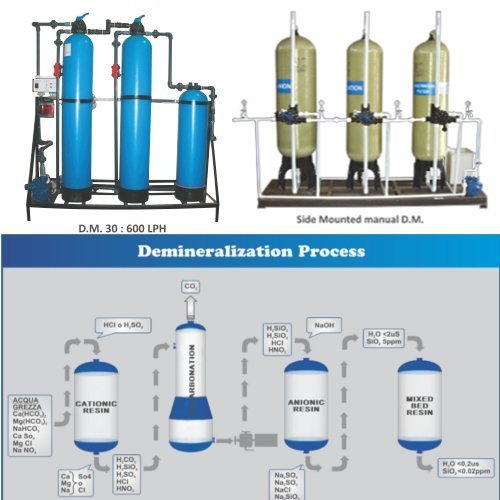

Demineralization Plants

Each plant for the production of demineralized water is custom made whether it is 100 lph or 15 m3/hr.Demineralization Plant is designed with the following parameters.

- Raw water analysis

- Quality of product water

- Production of dm water per hour

- Regeneration period

- Automation & controls

System includes:

- Frp/msrl/ssrl pressure vessels

- Multi port valve/ball valve piping

- Ion exchange resins

- Sand/gravel/carbon

- Control panel with plc

- Pressure monitors

- Feed/ booster pump

- Level controller

- Batch controller

- S. S. / m. S. Powder coated frame

- Regenerate drums

- Std pvc/ pvc-u/ . S. Piping

Polisher:

- Non regenerative type

- Continuous high quality water

- Compact design

- Low equipment cost

- Negligible labor charges

- Lower to medium productions

Mixed bed:

- Regenerative type

- Low cost for production per ltr of water

- High equipment cost

- Fully automatize process

- Medium to higher productions

Pressure vessels:

FRP - fiber reinforced plastic – pentair international ltd, SSRL& MSRL - stainless steel & mild steel rubber lining are fabricated in-house with advanced manufacturing processes gives low maintenance, higher servicing life with space savings.

Lon Exchange Resin:

As a part of the best industry practice we only use mono dispersion resins having size distribution of 0. 6 mm through. Results in high quality, longer generation periods, low channeling with high pressure and shock resistivity and longer changing periods.

Multiport valves:

Instead of conventional six way valve type pattern we use new generation multiplexor valves (for small to medium systems) which not only reduces labor requirement but also saves space, reduces maintainer time during servicing and importantly very economical also.

Type: manual multiplier valves, automatic multiplier valves

Piping:

PVC/ PVC-u pipes and fittings are of George Fischer, Switzerland or any standard Indian make. S. S. Piping are custom made at our fabrication shop with elector polishing which makes it suitable for all purposes including pharma & electronic industry.

Automation & controls:

We offer following automation as part of the standard package. Even other can also be included upon customer request.

- Conductivity controls

- Level controls (raw water & product water tank)

- Auto regeneration

- Batch process auto cut offs

- PLC based sync with other plants

- Pressure controls

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.